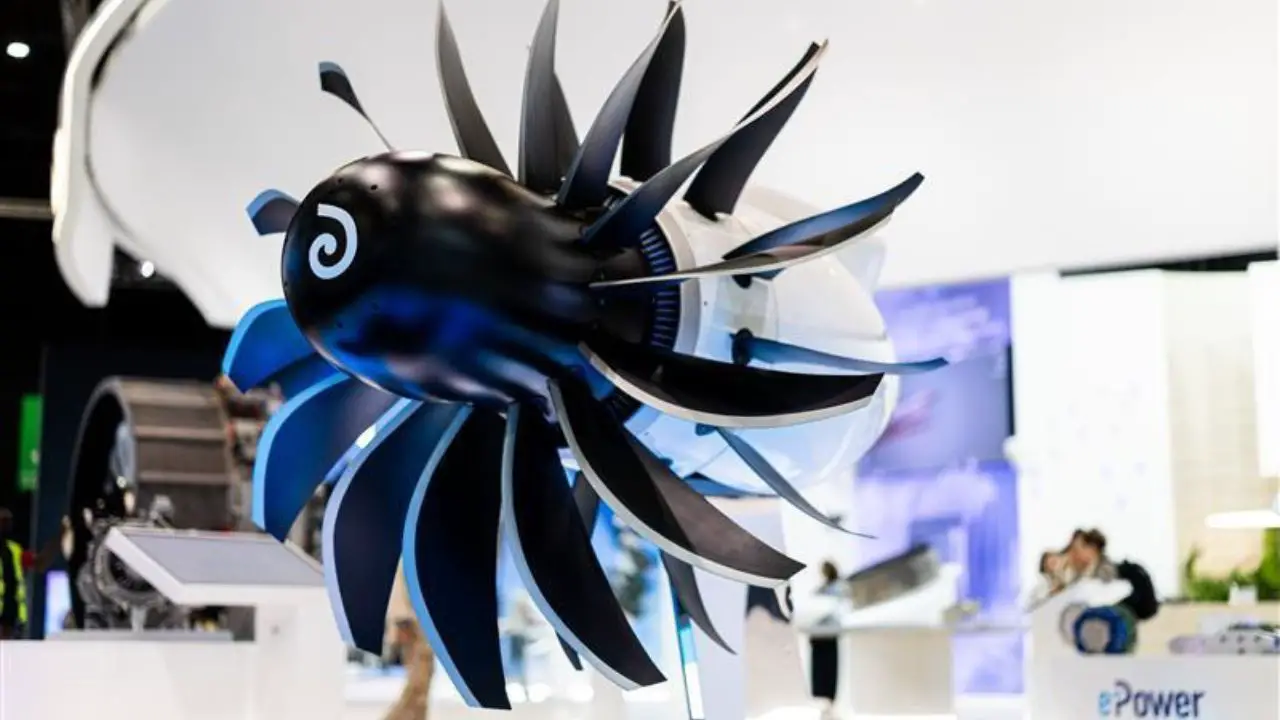

Safran Aircraft Engines, a French aerospace company, is at the forefront of the development of the next iteration of open rotor propulsion under the Revolutionary Innovation for Sustainable Engines (RISE) program, which is a joint venture between GE Aerospace and CFM International. This ambitious endeavor aims to revolutionize aircraft engine technology by incorporating cutting-edge aerodynamic, mechanical, and acoustic innovations. The most recent patent filings offer a captivating perspective on the technical innovations that Safran and GE are developing to address the conventional obstacles of open rotor engines. The primary objectives are to enhance operational safety, reduce pollution, and improve operational efficiency.

Significant advances in technology

The introduction of vortex recovery vanes with sawtooth edges is one of the patent’s most notable innovations. These vanes are positioned immediately behind the open rotor fan and are intended to mitigate the chaotic airflow produced by the rotating blades. The swirling flow, if left unmanaged, leads to significant aerodynamic losses that reduce thrust and overall engine efficiency. The energy in the swirl is effectively recovered and converted into additional propulsion by the swirl recovery vanes, which straighten the airflow. The aerodynamic performance of these vanes is not the only benefit of the sawtooth or serrated edge profile; it also plays a critical role in noise reduction. The serrated edges of open rotor engines disrupt the formation of strong pressure waves between blade rows, thereby mitigating the noise emissions that would otherwise propagate directly into the environment, as they lack the protective nacelle that typically contains and dampens noise. The RISE program’s objective of developing a commercially viable open rotor engine is fundamentally centered on the dual function of enhancing efficiency and reducing pollution.

The implementation of protective blades that are specifically designed to manage foreign object debris (FOD) is another noteworthy innovation. Open rotor engines are inherently more susceptible to environmental hazards, including ice, stones, and other detritus, which can result in severe damage if they are ingested into the engine core. Safran’s patents describe a set of rotating blades that are located behind the fan but before the guide vanes in order to reduce this risk. These blades rotate in tandem with the fan, producing a centrifugal force that efficiently chops or cuts foreign objects into smaller parts, thereby minimizing the potential damage they could cause. Furthermore, the centrifugal force propels debris outward, away from the engine’s core flow inlet, thereby enhancing the internal components’ protection. This innovation is of paramount importance in guaranteeing the durability and dependability of open rotor engines, which are required to function securely in a diverse array of environmental conditions.

The patents also verify the integration of a transmission between the low-pressure shaft and the fan, a feature that has become a defining characteristic of next-generation engine designs. The gearbox enables the low-pressure turbine to spin at a faster rate, thereby optimizing power extraction, while also allowing the fan to rotate at a slower, more aerodynamically effective speed. This decoupling of rotational speeds is essential for the RISE program’s main goals of improving fuel efficiency and increasing bypass ratios. Additionally, the fan’s noise reduction is facilitated by operating it at reduced velocities, which addresses one of the main obstacles to open rotor technology. The potential of RISE as a future replacement for conventional narrow-body jet engines is indicated by the inclusion of a geared fan system, despite the fact that it is presently in the demonstrator phase. This system guarantees substantial fuel savings and environmental benefits.

The Crucial Function of Guide Vanes

The patents underscore the critical function of guide vanes, which are also referred to as stator vanes and are located behind the fan. The airflow departing the fan blades is managed by these vanes, which are indispensable. The absence of guide vanes would result in considerable aerodynamic losses due to the flowing airflow, which would result in a significant reduction in engine efficiency and thrust. The guide vanes rectify the airflow, converting the rotational energy into useful axial thrust and smoothing the flow for downstream components. This process not only improves the overall efficacy of propulsion but also guarantees the stable operation of the engine in a variety of flight conditions. It is imperative to optimize the advantages of the open rotor configuration while minimizing losses through the meticulous aerodynamic design of these vanes.

Noise Control: Open Rotor Challenges and Solutions

Given the exposed blade architecture of open rotor engines, noise reduction is of the utmost importance. In contrast to conventional turbofans, which are housed in nacelles that aid in the containment and reduction of pollution, open rotors enable sound waves produced by blade interactions to spread directly into the environment. The patents propose stator blades with serrated leading edges to address this challenge. These blades disrupt the aerodynamic interactions between successive arrays of blades, which typically generate noise emissions. The engine is more acceptable for commercial use near airports and populated areas due to the serrated design, which reduces tonal pollution and breaks up pressure waves. The RISE program tries to address one of the main obstacles to the widespread adoption of open rotor technology by including these noise-mitigating features.

Protection from FOD

In comparison to ducted engines, the risk of foreign object debris ingestion increases significantly due to the open nature of the rotor. The rotating protective blades, positioned between the fan and the guide vanes, significantly reduce this risk. These blades serve as a primary line of defense, chopping and expelling debris prior to its entry into the engine core. This proactive approach safeguards the engine’s internal components from injury and extends maintenance intervals by reducing the size and impact of foreign objects. Also, the spinning action helps to throw out harmful materials before they can enter the engine, which makes the engine more reliable and safer. This innovation is a critical enabler for the practical operation of open rotor turbines in various environments.

Gearbox Integration: A Next-Generation Standard

Modern engine architecture stands out due to the presence of a gearbox between the low-pressure shaft and the fan, which enables the optimal rotational rates of various engine components. The gearbox allows the fan to operate at slower speeds that are more conducive to aerodynamic efficiency and noise reduction by decoupling the fan speed from the turbine speed. In the RISE program, this design approach is currently being refined and adapted for the open rotor configuration, following its successful implementation in geared turbofan engines. The gearbox is instrumental in the reduction of emissions and pollution, as it enhances fuel efficiency and facilitates the implementation of high bypass ratios. Safran’s patents suggest that the RISE engine uses this technology to expand the limits of sustainable aviation propulsion.

RISE Program: Objectives and Impacts

The RISE open rotor engine represents a daring vision for the future of commercial aviation. Its primary objective is to accomplish a fuel burn reduction of over 20% in comparison to the most advanced narrow-body engines currently in service. This substantial efficiency improvement directly correlates with decreased CO₂ emissions, thereby bolstering the industry’s overarching objectives for environmental sustainability. Additionally, the engine is being developed to be compatible with Sustainable Aviation Fuels (SAF) and potentially hydrogen, due to the changing energy landscape and regulatory frameworks. RISE is a promising candidate to replace conventional single-aisle aircraft engines, offering airlines significant operational savings and assisting in the fulfillment of increasingly stringent environmental standards, despite its current status as a demonstrator. The RISE program is a comprehensive reimagining of propulsion that has the potential to redefine the future of air travel, thanks to its innovative aerodynamic features, noise reduction technologies, and robust FOD protection systems.

Official Website of Youtube Channel – Altitude Addicts